Kellè news

Iscriviti alla newsletter per ricevere aggiornamenti su eventi, collezioni e promozioni esclusive.*Acconsento al trattamento dei dati forniti ai soli fini promozionali da parte di Kellé Capri.

Content

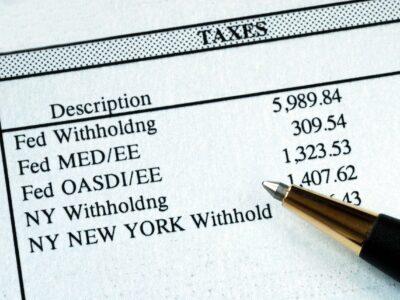

When you partner with a 3PL, you can automate your entire ecommerce fulfillment process. They should have real-time inventory reports that detail exact inventory levels in their warehouses. It can be very hard — and expensive — to scale your warehousing and inventory tracking. Once you start selling thousands of orders each month, you will be turning over inventory quickly and likely expand into new locations and stores.

Best of all, you don’t have to invest in a warehouse, land, infrastructure, equipment, warehouse management system, and workforce, or learn the ins and outs of operational protocols and regulations. 3PLs should be able to help you use historical data to understand when you’ll need to send more inventory to prevent stockouts. A reorder point or level is the specific amount of stock remaining for a certain item at which it needs to be replenished or refilled. Reorder points are essential for preventing stockouts (situations where a seller runs out of stock).

Inventory management systems provide all the information you need to keep track of your inventory, eliminating any paperwork. Therefore, inventory tracking operations through various techniques aim to keep the inventory volume at a planned level that allows achieving the highest economic benefit for the organization. And all of these things facilitate the process of managing inventory in general, as well as facilitating the tracking of all daily procedures.

This is really helpful if your business has multiple locations or sales channels, where one location may have sold the last of an item. With manual tracking, you don’t get the same automation and so it can be hard to track inventory quantities in real time. By leveraging automated replenishment features and demand-based decision-making, inventory tracking software helps prevent overstocking and ensures timely order fulfillment. This data-driven approach optimizes inventory management, reduces costs, and maximizes space utilization.

Firms which adopt just-in-time methods must make sure they have accurate demand forecasts and a thorough understanding of customers’ purchasing habits. Inventory tracking, as the name suggests, refers to the tracking of stock levels throughout a business’s what is inventory tracking operations. We’ll start by defining what inventory tracking is, then listing the key benefits and challenges involved. After that, we’ll discuss how to track inventory and look at inventory tracking compared with supply chain management.

What most people don’t realize is how complex a 3PL fulfillment company’s order fulfillment services are. If you’re looking for a solution for inventory tracking, ecommerce order fulfillment, returns management, and these other areas, a 3PL may be exactly what you’re looking for heading into the 3 quarter and beyond. However, large companies use software and if you want a more efficient fulfillment process, you’d use software too. This unique identifier — often a scannable barcode — can be used to track inventory from receipt to warehouse management and through to order fulfillment. This means you can track how much of each product you have and where each item is located. Unlike universal product codes (UPCs), SKUs are unique to your business and can be customized to fit your needs.

This can also enable you to improve your workflow, customer service standards, and the general customer experience. On the face of it, tracking inventory with spreadsheets (or even pen and paper) is a low-cost practice. But unless you’re super-organized, manual inventory tracking is prone to errors that can actually end up costing you money.

Inventory tracking can be as simple as maintaining a spreadsheet with product details and quantities or as sophisticated as using a dedicated inventory management software. Inventory models are mathematical equations or formulas that help businesses control their inventory, anticipate demand, manage reorder points, and minimize costs. The two most popular inventory models are the Economic Order Quantity (EOQ) model and the Just-in-Time https://www.bookstime.com/articles/what-is-a-professional-bookkeeper (JIT) model. They are used in businesses such as grocery and other retail stores whose inventory consists of finished goods. The e-commerce fulfillment process can be fully automated when you partner with a 3PL provider. They can offer you real-time inventory reports, send orders directly to customers, and provide e-commerce order tracking that can be passed on to the customer to monitor the status of their order at all times.

When ordering goods, they also must keep in mind promotional activities created by brands. Grocery stores track, monitor, and reorder inventory to ensure that items are available when customers need them. Supermarkets and grocery stores deal with far more complexity when managing inventories than most other retailers.

Depending on how your accounting system is set up, drop shipments are often not recorded as inventory but, rather, are frequently posted directly to the “Cost of Goods Sold” portion of your accounting system. Grocers know that analyzing weekly data is helpful in managing the inventory of many items, especially packaged staples and nonperishable goods. Grocers that don’t make use of that granularity of data analysis can lose out on sales because of stockouts; conversely, they can suffer an undue amount of spoilage by over-ordering.

Non ci sono prodotti nel carrello.